Department of Chemical Engineering

- About the Department

- Mission and Vision

- HOD’s desk

- Faculty Members

- Advisory Board

- PEOs and POs

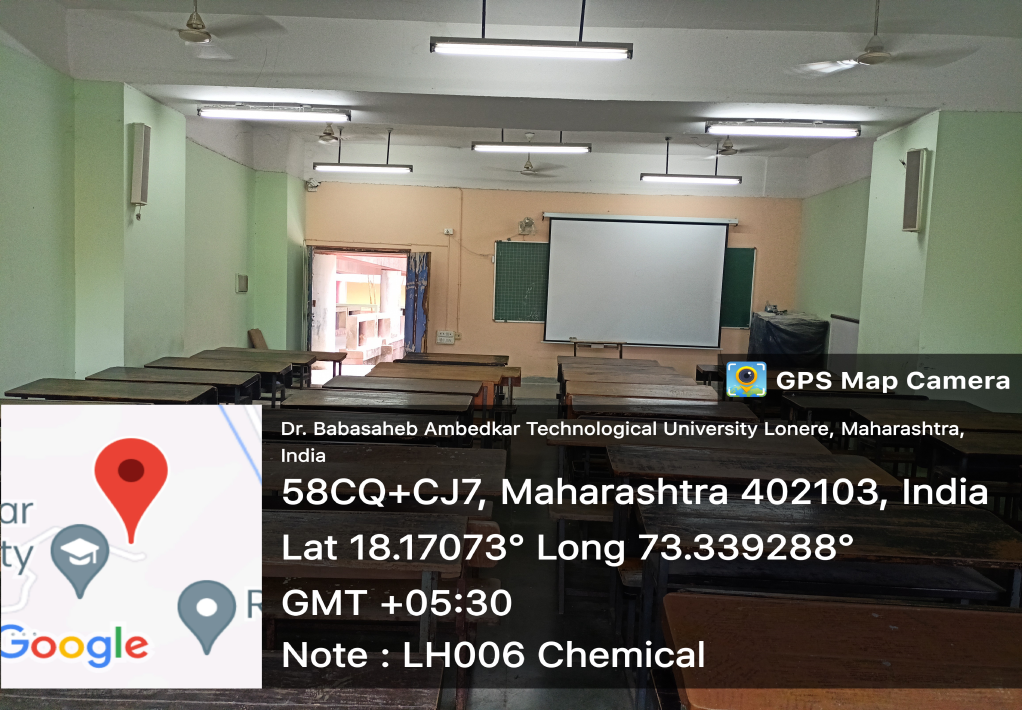

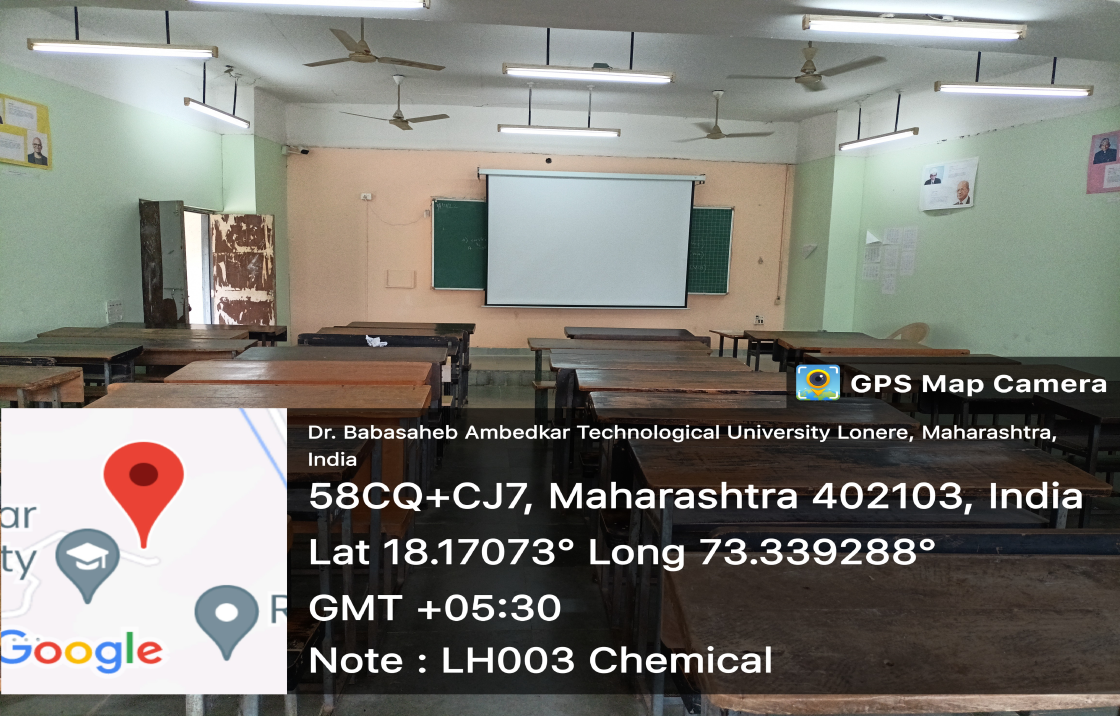

- Classrooms

- Laboratories

- List of Experiments

With a B. Tech. programme intake of 60 students, the department of Chemical Engineering was founded in 1992. With an intake of 16 students each, the M.Tech programmes in Chemical Engineering and Environmental Engineering were started in 2000 and 2001, respectively. The department also began a Ph.D. programme in the 2003 - 2004 academic year, and it holds the distinction of having graduated the first Ph.D. in the University. The faculties in the department are a committed group. Most of the faculty members hold doctoral degrees. The department has worked in conjunction with ICT Mumbai to execute cutting-edge research initiatives. The department's main goal is to turn out top-notch engineers with solid chemical engineering fundamentals. The TEQIP programme, a quality improvement initiative supported by the World Bank, is one in which the department has taken an active part. Additionally, the department has received funding for a variety of research initiatives from AICTE, UGC, ONGC, and DST. To support the research programmes, the department has excellent analytical capabilities. At the conclusion of the second and third years of the B. Tech programme, the students must complete industrial exposure and training, respectively, in accordance with the curriculum requirements. To help students understand the theoretical aspects, the department also arranges industrial tours of adjacent chemical industries. The conferences, seminars, workshops, paper publishing, annual sports, and other events, all encourage students participation. With the assistance of the business community, the department and the Chemical Engineering Association (ChEA) routinely host "Chemfraternity," a state-level technical festival. The Department of Chemical Engineering is one of the most preferred destinations in the state of Maharashtra.

Vision The vision of the department is to get national recognition for undergraduate Chemical Engineering program coupled with research strengths in the areas of Heat Transfer, Systems Engineering, Mass Transfer with Chemical Reactions and Biochemical Engineering.

Mission We provide a high-quality education experience that will prepare graduate to assume leadership positions within chemical and other associated industries. We foster and encourage the pursuit of new knowledge and innovative scholarship in chemical sciences and engineering. We provide leadership to the chemical engineering profession through dedicated teaching and service.

Quality policy: Committed to imparting quality education by student cantered teaching, learning training and placement process to achieve student in all endeavour leading to degrees in engineering and Management. To remain accountable in our core and support function, through continual improvement and meeting applicable requirements.

HOD’s desk

Dr. A. R. Chavan

Professor and Head

It is my pleasure to introduce the Department of Chemical Engineering at the main campus of Dr. Babasaheb Ambedkar Technological University, Lonere.

The Department is focused to impart quality technical education to the students so that they will be ready to serve the chemical and allied industries. For better prospects in professional life, we aim to get Industry-sponsored internships and projects for our B. Tech and M. Tech students.

The department works to provide students with an excellent education while also instilling a positive culture in them. Because of this, the department's graduates do incredibly well in both the workplace and academics.

For their graduate studies and professional careers, the Department offers a variety of guidance. The students are given GATE and other competitive exam guidance. During Chemfraternity, students get valuable experience organizing various activities. The department is particularly eager to host professional talks for the students by inviting distinguished speakers from IITs, ICTs, NITs, and from industries. The department maintains a good working relationship with the adjacent industries at Patalganga, Mahad, Roha, and Lote-parshuram.

In order to help all of the students develop fully in the field of chemical engineering and to better equip them to meet difficulties on a global scale, the department will continue to assist and encourage them.

Advisory Board: To provide guidance to the department, advisory Board has been constituted. The Advisory Council/ Board is entrusted with responsibility of conducting academic audit of department, suggesting dynamic curriculum and providing input for research activities. The Advisory Board comprises of the following persons.

| Sr. No. | Name | Designation |

|---|---|---|

| 1. | Head, Chemical Engineering, DBATU, Lonere | Chairman |

| 2. | Shri. Mahesh Purohit, Sr. VP(works), Vinati organics Ltd, Mahad | Member |

| 3. | Shri. Vivek Thorat: Asso VP(Operations), Godrej Astek, Mahad | Member |

| 4. | Dr. Rajkumar Sirsam, Department of Chemical Engg, UICT, NMU, Jalgaon | Member |

| 5. | Dr. Sachin Mandavgane, Department of Chemical Engineering, VNIT, Nagpur | Member |

| 6. | Dr. Sanjay Kamble, Principal Scientist, Chemical Engg and Process Development Division, NCL, Pune. | Member |

| 7. | Shri. Joy Thakur, Deputy Secretary and Scientist I, Environmental Department, Govt of Maharashtra. | Member |

Program Educational Objectives (PEOs)

- To provide knowledge of sound mathematical principles underlying various concepts of Chemical Engineering.

- To develop ability to understand complex issues in the analysis, design, implementation and operation of Chemical Engg. Systems.

- To provide knowledge of mechanisms for building large-scale Chemical-based systems.

- To develop ability to provide Engineering– based solutions to the problems from other disciplines of science and engineering.

- To impart skills necessary for adapting rapid changes taking place in the industries.

- To provide knowledge of ethical issues arising due to deployment of new technologies in the society on large scale.

Program Outcome (POs)

- The graduates will possess the knowledge of various discrete mathematical structures and numerical techniques.

- The graduate will demonstrate the use of Logic in representing and reasoning knowledge based systems.

- The graduates will have an ability to apply mathematical formalisms of to analyze the problems.

- The graduates will have knowledge of design software and concepts essential to implement these software.

- The graduates will have an ability to analyze problem, specify most feasible solutions to them and to evaluate alternative solutions.

- The graduates will have in-depth knowledge of core subjects of Chemical Engineering.

- The graduate will have broad understanding of the impact of Chemical Engineering solutions in economic, environmental and social context.

- The graduates will demonstrate use of analytical tools in gathering requirements to provide feasible solutions.

- The graduates will have knowledge of design rules and patterns necessary to formulate concept based solutions.

- The graduates will demonstrate the ability to build human centric interfaces to design tools.

- The graduates will possess skills necessary to communicate design engineering ideas. The skills set include verbal, written and listening skills.

- The graduates will have an ability and attitude to address the ethical issues.

Classrooms

- List of Experiments (Fluid Flow Operations):

- Determination of flow regimes -Reynolds’ apparatus

- Verification of Bernoulli’s equation

- Determination of Fanning friction factor for smooth and rough pipes

- Determination of equivalent length of pipe fittings

- Determination of viscosity with capillary tube viscometer.

- Determination of friction factor for flow through packed bed.

- Determination of discharge coefficient for venturi meter

- Centrifugal pump characteristics

- Study of Rotameter

- List of Experiments (Mechanical Operations):

- Determination of screen effectiveness

- Dry screen analysis

- Wet screen analysis

- Study of sedimentation

- Study of air elutriation

- Study of cyclone separator

- Study of froth flotation

- To determine thermal conductivity of given metal rod

- Study of Double Pipe Heat Exchanger

- Study of Shell and Tube Heat Exchanger

- Study of Study of emissivity of circular discs with and without black coating.

- Study of Stefan-Boltzman’s constant

- To determine the surface heat transfer coefficient for a vertical tube losing heat by natural convection.

- Determine activation energy of acid catalyzed hydrolysis of methyl acetate.

- To study effect of concentration of reactant and temperature on the rate of reaction.

- To determination of specific reaction rate of acid catalyzed hydrolysis of ethyl acetate

- Determination of specific reaction rate of acid catalyzed hydrolysis of ethyl acetate by sodium hydroxide at 298 K

- To study the reaction between potassium persulphate and iodide

- Kinetics of hydrolysis of methyl acetate by strong acid.

- To study saponification of ethyl acetate.

- Study of Isothermal continuous stirred tank reactor

- Studies on gas-liquid-solid reaction using hydrodynamic cavitation- carbonation process

- Polymerization of acrylic acid in a batch reactor.

- Demonstration of nitration reaction in Microreactors

- Demonstration of Microwave Reactor

- Demonstration of Ultrasound Probe Reactor

- Kinetic studies using Dilatometer.

- To determine the time constant of given thermometer with positive step change.

- To determine the time constant of given thermometer with negative step change.

- To determine the time constant and valve properties of single tank system.

- To study the step response of two tank non-interacting liquid level system and compare the observed transient response with the theoretical transient response.

- To study the step response of two tank interacting liquid level system and compare the observed transient response with the theoretical transient response for the condition T1=T2=T.

- To study the impulse response of a tank.

- To study coupled three or four tanks system.

- To study any inherently second order system.

- To study different types of controllers.

- Heat Exchanger

- Absorption column

- Distillation column

- Reactor

- Evaporator

- Flow sheeting of a chemical plant

- Simulation of a small size chemical plant.